- September 15th, 2014

- /

- Pocket Hole Accessories, Pocket Hole Joinery Tips

- /

- 0 Comments

- /

- Review of the Kreg Foreman DB210

Before starting this review I went to Kreg’s website to read some user comments on the new DB210. I was surprised at how many people complained about the price!? I bought the original Kreg foreman for 800.00 in 2007. At the time of purchase I was a bit hesitant with the high cost but after using it on a job I knew that over time it would pay for itself and it has. It is a rugged fast pocket hole machine. I have a few complaints with the old DB110, mostly it’s difficult to change the drill bit, fence, and depth stop settings. Its a heavy machine, bit hard to carry and the dust port is kinda useless but the machine is so simple to use and fast. It makes drilling out a stack of cabinet parts a piece of cake. When Fine Woodworking magazine approached me about reviewing the new Foreman DB210 I jumped at the chance. I wanted to see if they addressed my complaints. I’m happy to report that the new Foreman DB210 is pretty much a home run. There are a few issues that I’ll address but over all it’s a great machine at a great price.

When you look at the original foreman DB110 next to the new DB210 they look to be the same size. The older foreman has a motor that turns on when you pull on the lever, the new foreman has a trigger. This is a nice safety feature as sometimes on my DB110 if you accidentally pulled the handle the motor would turn on and startle you.

The clamp and drill bit depth stop are very easy to adjust without having to open up the machine.

simply turn the knob to adjust for material thickness. A nice rubber pad on the end of the clamp helps protect the work.

At the back of the machine is the drill bit depth stop adjusting knob. Either eye ball it or use the depth adjustment block.

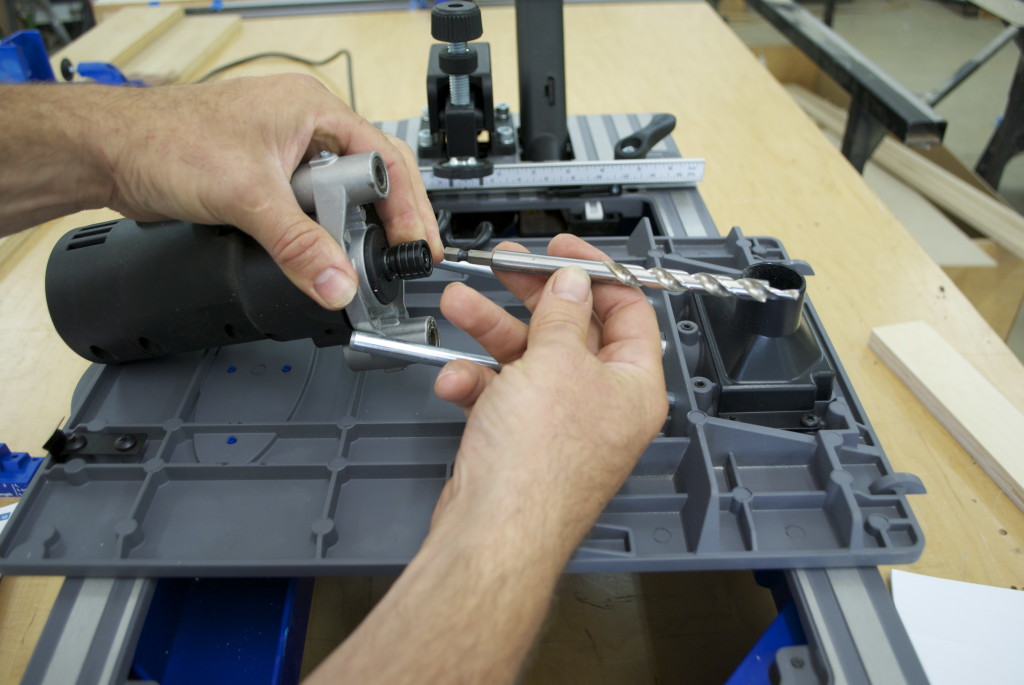

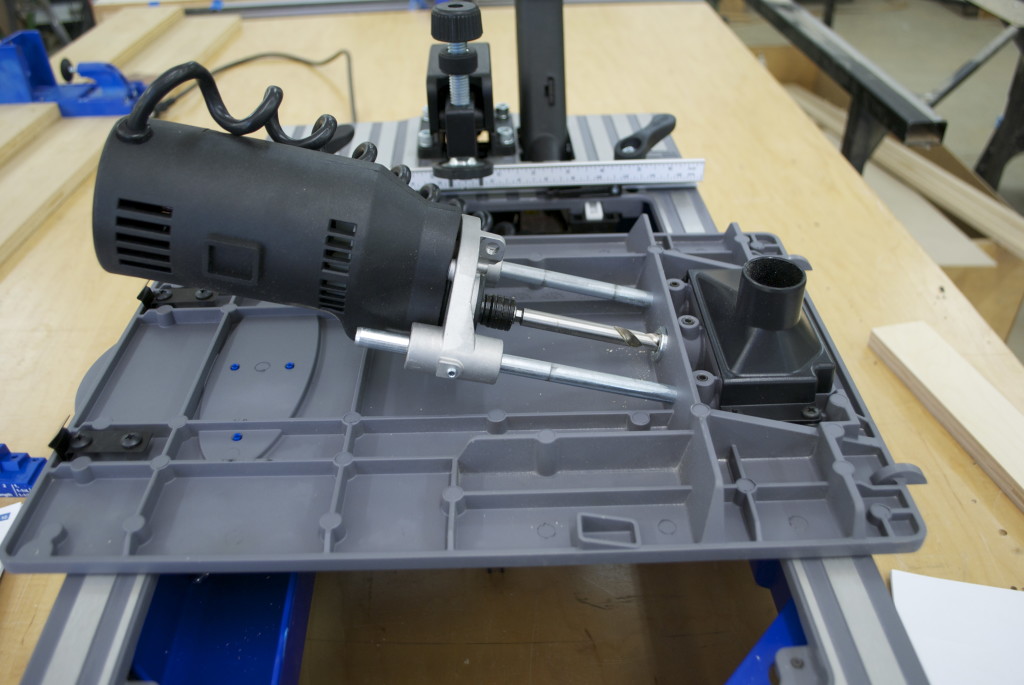

Pulling the motor out is much easier on the new DB210. Simply tip the center panel up and pull the quick pin. The drill bit pops out with a quick release chuck. This takes seconds compared to minutes on the original DB110.

On my older DB110 the drill bits were extra long and thus more expensive and harder to find. The new DB210 uses the standard drill bit which will save you some money.

On the right hand side you can see the dust port. This hooks to an included hose and connects directly to your vacuum system via a port on the back

The fence is very easy to adjust by turning this knob and there are hash marks on the top to help properly locate it

There are two very small material stops that stay out of the way until they are flicked out. You adjust their location with an allen wrench. Its a little tricky to get the allen wrench in the tiny screw head. Also these don’t lay completely out of sight when not in use. One of my few complaints that really doesn’t add up to much in the way of inconvenience.

I drilled a lot of holes with both machines and the differences were sublte considering the 400.00 savings with the new DB210

Now that I’ve listed all of the improvements let me touch on a few things that I guess would be considered complaints. First the motor seems to be a bit smaller on the new DB210 compared to my original Foreman. It’s only noticeable when drilling very dense hardwoods like hickory. The new DB 210 drills the holes fine, but when drilling side by side with the older foreman you do notice it. Second, the work top on the new DB210 is aluminum with grooves for debre. This is nice as it cuts down on small bits of wood that might mar your work but there is more friction when sliding the work across the table then there was with my DB110 which has a smooth hard plastic surface. Third the small stop blocks that store out of the way under the fence, well they don’t story completely out of the way. They stick out just under 1/8″. This is minor and easy to compensate for and my guess is that it will be fixed on later models. Call it a blip on a new tool release. Finally there is something I notice when drilling the holes with the new DB210. The motor is mounted to a table insert that is easy to remove. There is just a slight amount of play between the table insert and table cut out. When drilling holes this insert and the motor housing seems to shift ever so slightly to the right. Due to the direction of the drill motor. It’s not stressing out the bit or hole since the work and insert shift at the same time but you see it. It doesn’t happen with my DB110 since the motor is mounted to the table. Not sure if this is a complaint as its just something I noticed and wanted to mention.

Lets end on a couple of positive notes. The new DB210 can use different sized drill bits and drill bushing for drilling pocket holes in narrow stock and very large 2x material. This is a very cool addition, something my DB110 won’t do but must be purchased separately. The new Kreg Foreman DB210 is a great machine with tons of improvements over the old DB110. The price savings is huge. The difference between drilling holes with the more affordable kreg gigs and the foreman DB210 is monumental. Hopefully those of you who enjoy using pocket hole joinery will get to discover how much easier it is to drill holes with the new DB210